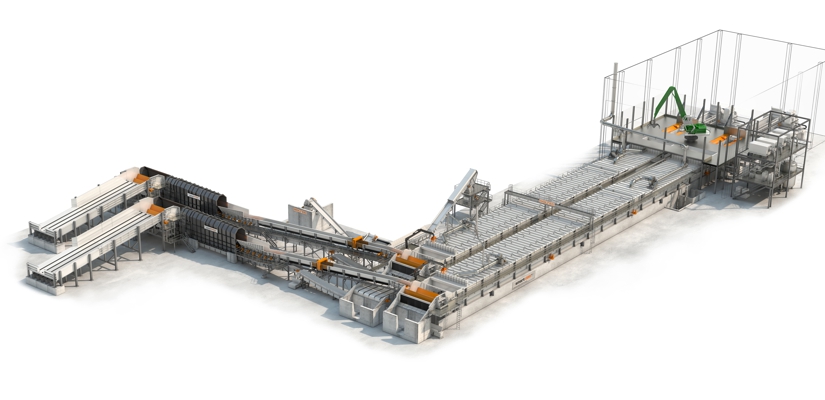

- HOLTEC De-Icing-System „smart-con“

With this technology developed by HOLTEC, the working principle of the logponds is “upended”. The logs lie onto a chain conveyor. By means of this conveyor they are transported through a continuous water curtain. The waste water is gathered at a central position, automatically cleaned and heated up again.

Advantages of this technology:

- Automatic water cleaning, i.e. no settling of dirt and mud in the basin

- Constant temperature distribution in the total cross-section

- Free access in case of damage

- High water temperatures of >70°C possible

- Very low amount of water in the circuit

- System lengths up to 70 m

- Log lengths 3 - 6 m

- Capacities 20 - 100 t/h

- Supply incl. complete heating technology possible

Log conditioning

A high chip quality is the basic condition for producing a premium final product with the guaranteed features. To be able to produce strands in a consistent good quality even in cold regions (especially North America and Russia), the logs need to be conditioned before being brought to the flaker. This means, in the freezing period the logs need to be thawed. Such a process leads to a low amount of fines and the lifetime of the flaker tools can be increased significantly.

HOLTEC offers different technologies:

- Logponds

The logs are conveyed continuously through a huge concrete basin filled with hot water. By means of chain conveyors the logs are kept below the water surface. Standardly the logs are unloaded by electrically operated material handling machines. In the basin there are laterally arranged recesses where radiators are installed for heating up the water.

- Engineering by Canadian specialists

- Conveying chains in North American design

- System lengths up to 70 m

- Log lengths 3 - 6 m

- Capacities 20 - 100 t/h

- Supply incl. complete heating technology possible