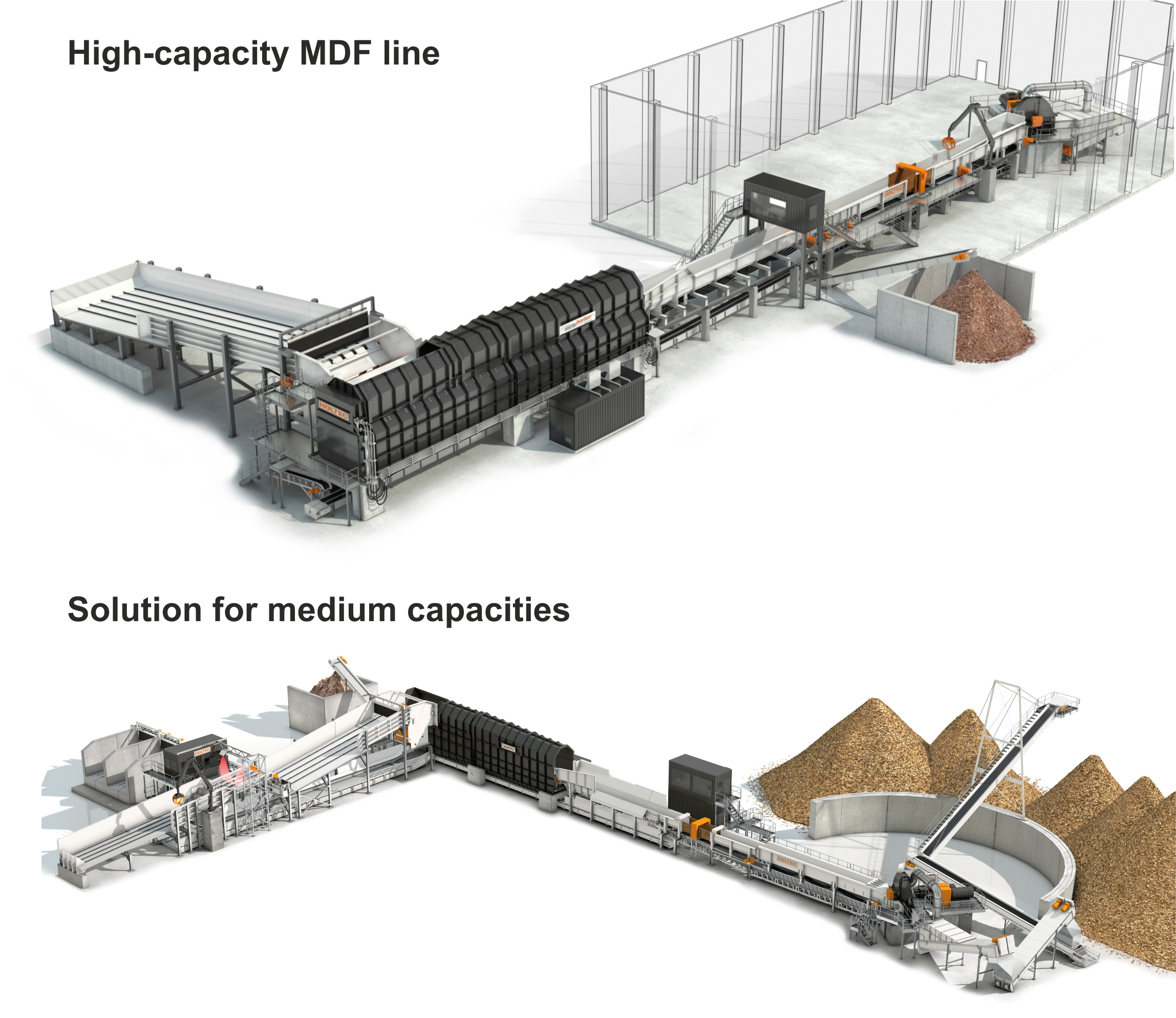

Logyards for the MDF industry

Premium products such as MDF or HDF plates require optimally produced chips as source material. Debarkers and chippers are the central machines. These machines need to be integrated by intelligent and reliable conveying technology so that they can show their full capacity. HOLTEC provides premium solutions for capacity ranges of 30-150 t (b.d.) chips /h.

As debarker we rely on the rotary debarker principal. The vario-barker developed by HOLTEC has been sold 15 times within five years. The machine’s inclination can be set hydraulically which is a unique feature on the market. Therewith the debarking result can be adjusted optimally depending on the raw material’s condition.

For MDF we clearly prefer the disc chipper technology. It grants an optimal chip geometry as well as a low amount of fines. Together with our partner we offer solutions with 2,800 – 4,000 mm disc diameter and up to 2,000 kW drive capacity.

We see ourselves as partner for the overall concept – from the log infeed to the chip handling. Our concepts are based on a careful process analysis and comprehensive engineering – without interfaces for the operator.

Erstklassige Produkte wie MDF-/HDF-Platten verlangen bestmöglich erzeugte Hackschnitzel als Ausgangsprodukt. Zentrale Maschinen sind hier die Entrindung sowie der Scheibenhacker. Um die Leistung beider Maschinen bestmöglich auszunutzen, müssen diese mit intelligenter und zuverlässiger Fördertechnik sinnvoll eingebunden werden. HOLTEC bietet hierzu erstklassige Lösungen für Leistungsbereiche von 30-150to. Hackschnitzel atro/h.

Feeding systems

Feeding systems

Reliable from the beginning: The efficient feeding of debarkers is a central element in the row of linked machines. The system capacity is decisively affected already at that point.

With the step feeder technology HOLTEC set a benchmark in the industry sector. Combined with a robust and heavy infeed deck this unit is used for capacities up to 100 t (b.d.) / h. Infeeds naturally have to bear the highest mechanical loads. Heavy chains with an extremely high life time ensure our customers that the “total lifetime costs”, i.e. the costs for the total operating time, are reduced to a minimum.

Debarkers

Debarker „variobarkerTM“ - HOLTEC

- Robust and solide Design. Driven by hydraulic Motors instead of chain drives.

- Improved debarking result by adapted tool geometry and tool arrangement at the rotor.

- Vario tilting function: Adaptation of the machine's inclination based on the different surroundingconditions (required capacity, log condition in Terms of temperature, humidity, etc.) This results in an active control as well as influence on the debarking result.

- Modular design for different production ranges.

- Different tools are possible, with active toothing – especially for the freezing periods.

- High degree of pre-installation – Reduces efforts at the construction site, reduces foundation works.

- Drive concept optionally hydraulically operated or with electric drive "E-drive".

Conveying systems

Conveying systems

Logyards in the wood based panel industry are often complex systems with a lot of linked machines and conveying systems. High feed capacity associated with highest standards of the availability are the basic conditions for the development of all conveying systems. We are familiar with log handling and benefit from nearly 50 years of know-how. We set new standards with our product range solid-plus for more than 15 years. Very tear resistant chains, special wear resistant steel and the necessary sophistication in the details characterise our conveying systems

Waste handling systems

Waste handling systems

Seems to be marginal and is often disregarded. Adapted to the application a suitably dimensioned waste handling is self-profitable. HOLTEC provides solutions from the scraper conveyor via the waste conveyor in chain execution to the conveyor band with metal detection. As core product to 100% from one source and designed as well as improved with a long-standing know-how.

Disc chippers

The disc chipper is perfectly suitable for producing high-quality wood chips. The typical field of application is the pulp industry as well as the production of MDF and HDF plates. The logs are automatically, i.e. without any additional infeed unit, pulled through the chipper disc into the machine. The chipper chips the logs with several knives which are radially arranged at the chipper disc. Due to this arrangement the logs are automatically pulled into the machine without a high power requirement. By menas of Slots in the chipper disc the chips are fed directly into the outfeed channel.

Together with our experienced Partner NYBLAD, HOLTEC offers an extremely robust machine, designed for a 24/7 operation. The design is influenced by the experience of WIGGER who is the pioneer in the fiel of disc chippers with more than 1,000 machines supplied. All parts that are in contact with wood are exchangeable and made of wear-resistant material.

The chippers are available with a horizontal infeed typr TAIFUN or as drop-down chipper with a material infeed from above type HURRICANE. The chip amount, its size and quality can be varied by adapting the number of knives as well as the rotational speed and cutting length.

Disc chipper „TAIFUN“ / HOLTEC-NYBLAD

- All system parts that are in contact with material are equipped with exchangeable, high-strength wear materials.

- Very smooth running by state-of-the-art manufacturing processes, no balancing of the chipper disc necessary as this is milled from solid material.

- Over-dimensioned steel bearing houses produced in-house.

- Shaft inserts with precision bore for a non-destructive exchange of the chipper disc or axis.

- Relieved Motor start-up by Turbo coupling between motor and gear box as well as elastic coupling between gear box and shaft bearing for sparing the gear box.

- Chip discharge after intermediate bin by 4 screw conveyors arranged in parallel.

- Experience from more than 1,000 installations.

- Alternatively available as drop-down chipper "HURRICANE".

Chip handling

Chip handling

Systems for the handling and storage of chips complete the HOLTEC product range on the logyard. The product portfolio includes the complete range of conveyors, from belt conveyors via chain conveyors to bucket elevators and screw conveyors. We design and manufacture our conveyors on our own or work together with professional partners.

Control and switch systems

Control and switch systems

Today systems in the wood industry are complex high-tech machines. With customer-oriented solutions HOLTEC provides the corresponding automation. From the switch cabinet construction to the process programming we produce the complete value chain in our own company and therefore, we have under control 100% of what our customers receive. Innovative programming with TIA Portal and Siemens S7-1500 are self-evident to us.

• Development of customer-specific hardware and software

• Production of electrical components and switch cabinet construction

• Installation and cabling of the delivered systems

• Start-up at site

Sorting industrial logs

Sorting industrial logs

With log shortages and increasing raw material costs, maximising the utilisation of raw material is critical to most businesses. Pre-sorting and classifying sawable log qualities can increase the added value. The sorted out sawable logs can either be used in the own sawmill (integrated sawmill) or sold. HOLTEC provides new solutions for high capacity log scanning on a cross conveyor.

Sort out the money on your logyard