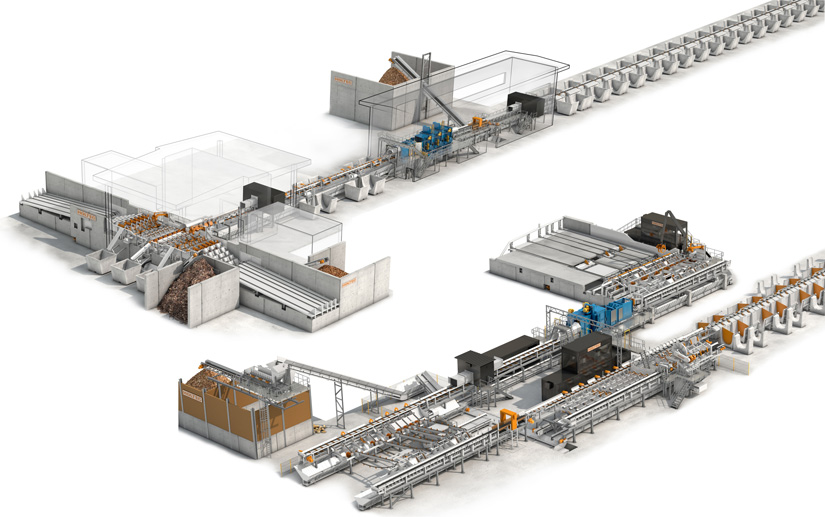

Conveying systems for long logs and short logs

High feed capacity and numbers of pieces associated with highest standards of the availability are the basic conditions for the development of all conveying systems. We set new standards with our product range solid-plus. Very tear resistant chains, special wear resistant steel and the necessary sophistication in the details characterize our conveying systems. Especially for accelerating short logs HOLTEC set the benchmark in its business sector by developing the v-shaped rollerway log-runner.

log-runner: THE innovation for accelerating logs - hundredfold proven.